Quality management

Quality is in the eye of the customer. It defines what aspects someone desires in a product and what it is worth to this person. The more of the aspect and the more aspects are fulfilled, the more value is added to the product and this influences its price. Quality management is not just about setting some standard or receiving some certificate, it's about a commitment that whatever the level of quality in our products, it will be improved continuously as long as we work.

Quality aspects are often defined by personnel within the supplying organisation, whereas the true view on quality comes from the customer. Realising this is the first step to quality management.

The world renowned ISO 9001 certification is tackled as a mythical beast that for some unfathomable reason will result in a certificate on our organisation door as long as we deliver some handbook with production processes documented in it. It is by no means mythical; if you realise that quality means added value which means higher prices for your products, then it becomes a direct part of the goal of any profit organisation. Finding out which steps to take to actually get certified then becomes as easy as 1-2-3.

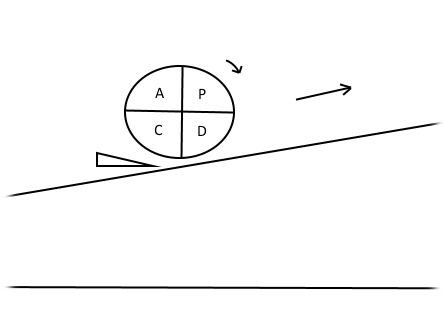

This image visualises the core of continuous quality management; in a continuously repeated process of Plan, Do, Check, Act, the current quality level is determined, improvements are designed and implemented and evaluated. After such a cycle, the resulting production processes are documented and embedded in the organisation so that lessons learned are never forgotten and searches improvement opportunities always build on what has already been achieved.